High Carbon Ferrochrome Furnace

High Carbon Ferrochrome Furnace

Product Description

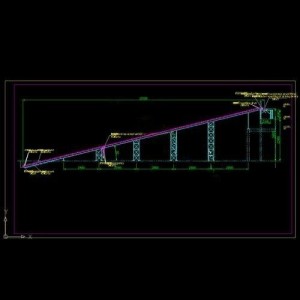

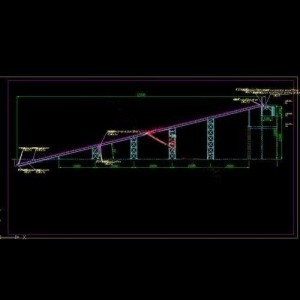

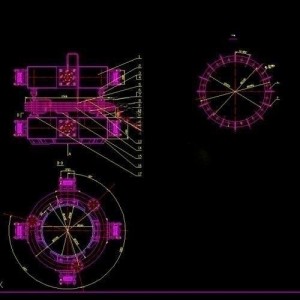

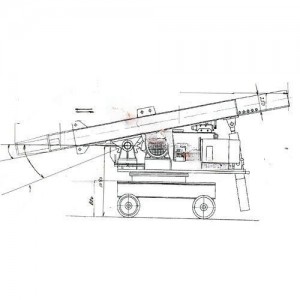

High carbon ferrochrome furnace, (HC FeCr SAF) is refers to high carbon ferrochrome alloys production process by submerged arc furnace. And blast furnace also can be used for production of such kind of alloys sometimes due to power supply can purity of raw ore.

Ferrochrome alloy, Ferrochrome/Ferrochromium (FeCr) is a type of ferroalloy, an alloy between chromium and iron, generally containing 50% to 70% chromium by weight.

High carbon ferrochrome is a carbon reduction product intermittently outgoing from the furnace. It is produced from ferrochrome minerals in electric smelting furnace for continuous smelting by using silica as flux and carbon as a reductant.

Ferrochrome production is essentially a carbothermic reduction operation taking place at high temperatures. Cr Ore (an oxide of chromium and iron) is reduced by coal and coke to form iron-chromium alloy.

Technical details of HC FeCr alloys are show in the following table:

| Grade | Chemical composition % | |||||||||

| Cr | C | Si | P | S | ||||||

| Purity | Ⅰ | Ⅱ | Ⅰ | Ⅱ | Ⅰ | Ⅱ | Ⅰ | Ⅱ | ||

| ≥ | ≤ | |||||||||

| FeCr67C6.0 | 62.0-72.0 | 6.0 | 3.0 | 0.03 | 0.04 | 0.06 | ||||

| FeCr55C6.0 | 60.0 | 52.0 | 6.0 | 3.0 | 5.0 | 0.04 | 0.06 | 0.04 | 0.06 | |

| FeCr67C9.5 | 62.0-72.0 | 9.5 | 3.0 | 0.03 | 0.04 | 0.06 | ||||

| FeCr55C10.0 | 60.0 | 52.0 | 10.0 | 3.0 | 5.0 | 0.04 | 0.06 | 0.04 | 0.06 | |

Usages of HC FeCr alloys:

High carbon ferrochromium is mainly used in stainless steel production, in which chromium content of 200 series stainless steel is about 16%, that of 300 series stainless steel is about 25%, and that of 400 series stainless steel is about 14%. 300 series stainless steel with the largest demand for ferrochrome is also the largest proportion of stainless steel products in the production.

At present, high carbon ferrochrome furnace is set up as big as 75000KVA~ capacity.