High Carbon Ferromanganese Furnace

High Carbon Ferromanganese Furnace

Product Description

High carbon ferromanganese furnace here refers to submerged arc furnace used for HC FeMn productions.

Submerged arc furnace and blast furnace are both can be used for high carbon ferromanganese production, by which carbon materials used as reductant. It mainly depends on chrome ore quality, power supply and other reasons.

Submerged arc furnace high carbon ferromanganese, with carbon content of 7%, is mainly used as a deoxidizer, a desulfurizer and an alloy additive in steelmaking process. And it can be used for medium/low carbon ferromanganese production with carbon content of 1.0~1.5% and 0.5%. Manganese content in Manganese ore must be 30~40% normally and sintering process is necessary for powder ore. High Carbon Ferro Manganese as the name suggests contains high percentage of carbon. It is mainly used in production of high quality stainless steel. A reduction of manganese ore is mixed with high carbon content coal and slag-forming constituents in a rotary kiln and exposed to high temperature to produce this alloy.

GENERAL SPECIFICATIONS of HC FeMn

| Mn | 70%-75% min |

| Si | 1.5% max |

| C | 6-8% max |

| P | 0.4%max |

| S | 0.05% max |

| Size | 10mm-100mm, As per customer request |

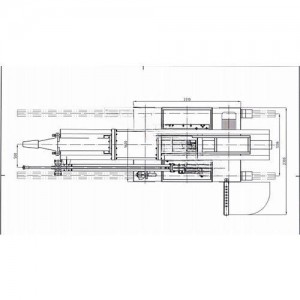

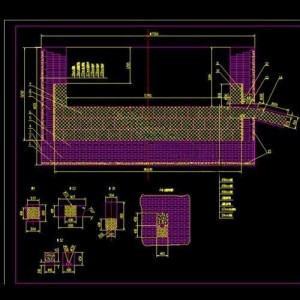

The capacity of modern large-scale high carbon ferromanganese furnace (SAF) is 40000-75000 KVA, which is generally fixed-closed type. Power consumption of smelting with flux method is generally 2500-3500 kw.h / ton, while that without flux method is 2000-3000 kwh / ton. Manganese silicon alloy is smelted by closed or semi closed reduction furnace. Generally, manganese ore with high silicon dioxide and low phosphorus content or additional silica is used as raw material. Rich manganese slag with low phosphorus and high silicon dioxide is a good raw material for smelting manganese silicon alloy. Power consumption of smelting is generally about 3500-5000 kw.h / ton. The raw materials, including pelletizing, preheating, pre reduction and powder sintering, are pretreated to improve operation and technical and economic indexes of submerged arc furnace.